New Products

Find Belt Driven Type Air Compressor, Belt Driven Rotary Screw Air Compressor, Belt-Driven Screw Air Compressor on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

Instructions before starting the Air Compressor:

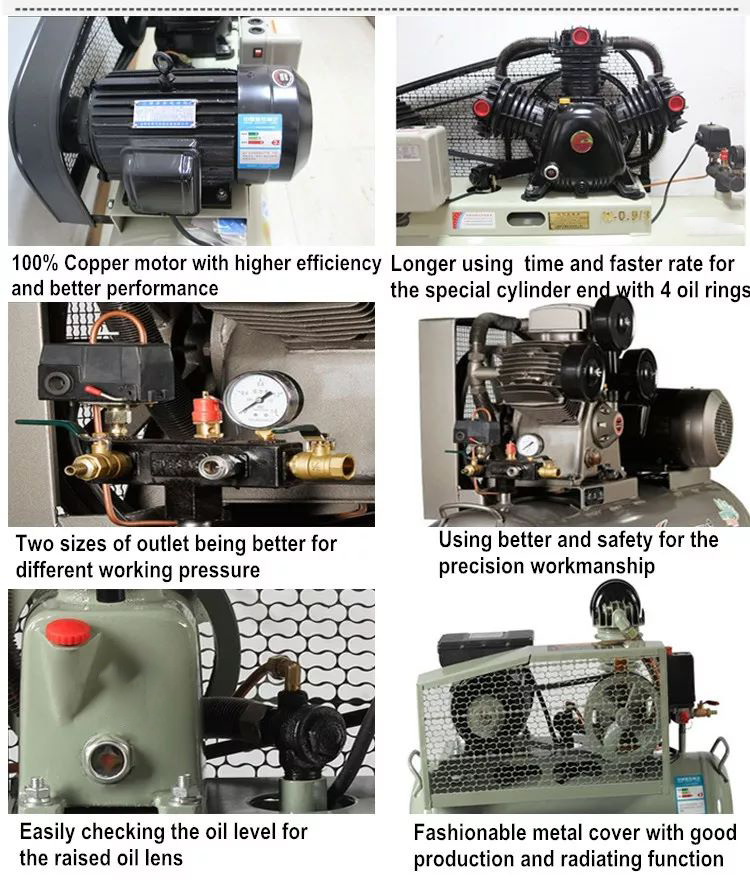

① Please check the oil level before starting the air compressor: is the oil level in the center of the red dot,

If it is lower than the red dot, please add oil to the center of the red dot before use, so as not to cause cylinder pulling!

Fujiwara air compressor has been added to the center of the red dot before delivery, so there is no need to add additional oil,

The oil level of the air compressor needs to be checked on time during the later maintenance of the air compressor.

② Before starting the air compressor, the breathing nozzle must be replaced: white on the cylinder near the belt

Remove the rubber glue or screw and replace it with the Yellow breathing nozzle in the accessory bag, otherwise the air will not breathe

Circulation leads to cylinder explosion. (rubber glue or screws are placed to prevent oil leakage during transportation)

mobile air compressor for tires (working principle)

The principle of Piston Air Compressor -- after the driving machine is started, the triangle tape drives the compressor crankshaft to rotate, and the piston is converted into reciprocating motion in the cylinder through the crank bar mechanism. When the piston moves by the cover side axis, the cylinder volume increases, the cylinder pressure is lower than the atmospheric pressure, the outside air through the filter, the suction valve into the cylinder; Arrived at the next check point, the piston lateral movement by the lateral axis cover, air suction valve closed, cylinder volume became smaller, the compressed air in cylinder, pressure increases, when the stress reaches a certain value, the exhaust valve is open, compressed air concession road into the storage tanks, so the compressor work repeatedly, constantly to the transmission of compressed air in the store jar, the tank pressure increases gradually, To obtain the required compressed air.

Advantages of mobile air compressor:

High reliability:

The compressor has few spare parts and no wearing parts, so it has reliable operation and long service life, and the overhaul interval can reach 40000 ~ 80000 hours;

Convenient operation and maintenance:

High degree of automation, operators do not have to go through long-term professional training, and can realize unattended operation;

Good power balance:

Without unbalanced inertia force, it can run smoothly at high speed and realize no foundation operation. It is especially suitable for mobile compressor with small volume, light weight and less floor area;

Strong adaptability:

It has the characteristics of forced gas transmission, the volume flow is hardly affected by the exhaust pressure, and can maintain high efficiency in a wide speed range.

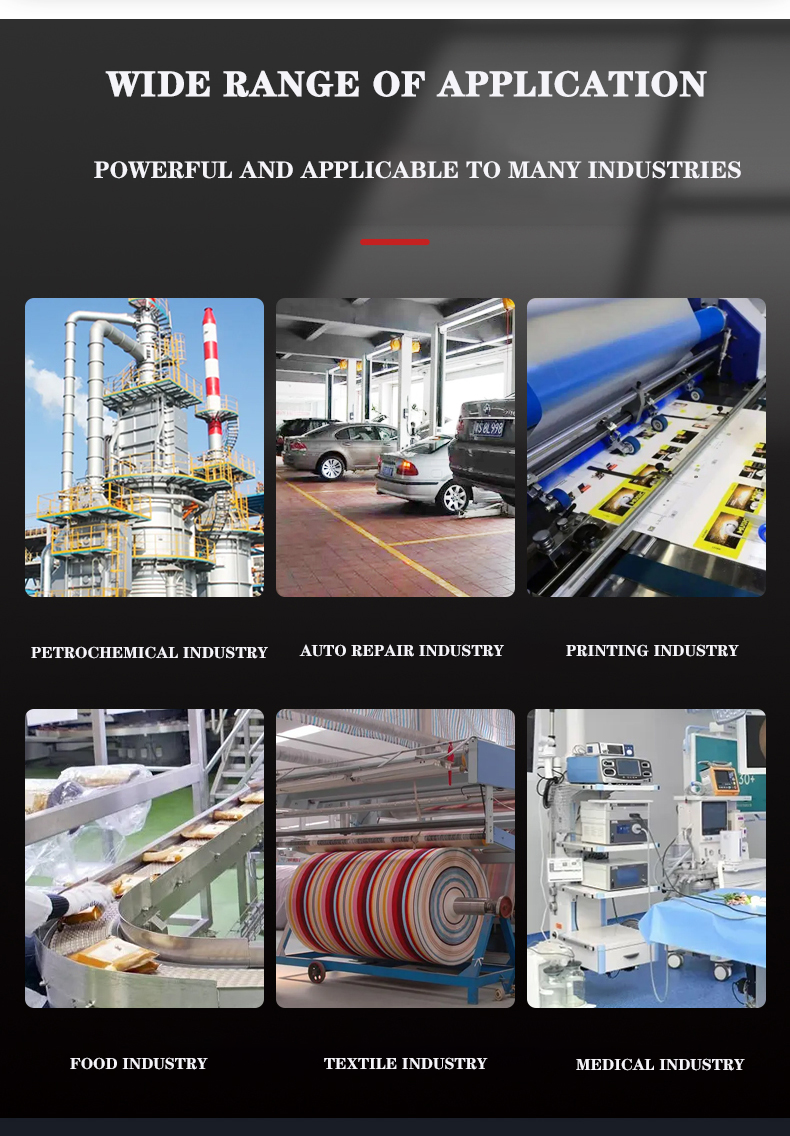

Use Scenarios

1. For nail machine guns

2. For the Spray Gun

Product Categories : Air Compressor > Belt Drives The Air Compressor